Installing split air conditioning systems and refrigerant systems with flared connections

Introduction

Installing split air conditioning systems and refrigerant systems with flared connections

Most split air conditioning systems are supplied with flared connections. These are potential points of leakage which can be avoided by:

- Removing the flares on the indoor unit and directly brazing the connections;

- Using flare solder adaptors on the pipe work to the outdoor unit.

This procedure has been documented to aim to promote the removal of flare nuts wherever feasible and the cost is not disproportionate for joints that could leak F-gas.

Installation for Minimum Leakage

The quality of pipe work and connections has a major impact on the future leak potential of systems.

- The type of joints used to connect pipes and components and how pipe is supported are fundamental to reducing the potential for leakage.

- This work should be undertaken by a trained and competent person.

- We accept no responsibility for the use or misuse of this guidance.

The Real Zero project has provided training for leak reduction specialists, guides, tools and a website (www.realskillseurope.eu/). The project (Refrigerant Emissions and Leakage Zero) was initiated by the Institute of Refrigeration, supported by the Carbon Trust and the RAC industry to provide practical guidance on reducing leakage.

There is a lot that can be done at the design stage to minimise leakage. The key is to design the pipe work carefully (to avoid stress related failures) and to use connections that remain leak free in all modes of operation. This approach does require attention to detail and may involve a small amount of extra capital cost. However, the extra investment will pay-off if the plant remains free of leaks. Designing the plant to hold the minimum quantity of refrigerant reduces the loss in the case of a catastrophic leak.

Ensure that personnel are appropriately qualified to install equipment – minimum qualifications apply for both installation, servicing and maintenance of F-gas containing equipment.

A study has shown that 96% of leaks are from field assembled joints. To minimise this leakage joints should be brazed wherever possible.

Mechanical joints are appropriate for some connections, for example for filter driers in smaller systems which cannot easily be changed if they are brazed in and the inlet to thermostatic expansion valves. In these cases flare solder adaptors should be used. These provide the ease of component change of a flared connection, with the reliability of a brazed joint.

Task Procedure for the Fitting removal of Flare connections and Replacing with Brazing Tails

AHU Units

- The work should be carried out in a suitably covered and dry safe area away from pedestrian or motorised activity that is well ventilated and free of combustible materials.

- Remove existing insulation from the pipe stubs.

- Providing there is more than 75mm of pipe protruding from the unit (less than this may be insufficient for brazing a section on to it), cut the flare/ flare nut off, with pipe cutters, as close to the flare as possible without the cutter wheels coming into contact with the flare. Care should be taken as some wall mount units have a strainer (the warranty may be affected if the strainer is damaged or removed) located close the inlet flare-it may be necessary to cut the strainer out and replace it with a new one.

- Any associated access covers/plates, where pipes are entering the unit, should be removed, if possible and any cables, insulation, plastic parts are going to be affected by the heat or the flame during brazing, directly or through conduction-shielding and the use of a wet rag, heat-sink compound or flame retardant gels may be required.

- If the pipe is to be swaged, do not use percussion type of tube expander i.e. Swage Punch as this could result in damage to the coil connections. Use only Expander/Swager** Heads of the correct size and that are suitable for refrigeration pipe. The temper grade of the pipe may deem it unsuitable for swaging, and therefore grades such Hard and Half Hard would need to be annealed beforehand.

- Prior to brazing, position the unit so that the pipe stubs are pointing upwards to ensure proper penetration of the filler and to conduct the heat upwards and away from the unit.

- (Wall) cut lengths of the same size pipes to be extended to a suitable lengths for your purposes e.g. to effect a bend or to allow them to go through a wall and insert into the swaged pipe whilst supporting it in position-this may need the assistance of a second person to hold it with pliers or other suitable tool.

- (Cassette) cut suitable lengths, this might be dictated by site conditions e.g. to access a suspended ceiling grid, of the same size pipes to be extended and insert into the swaged pipe whilst supporting it in position – this may need the assistance of a second person to hold it with pliers or other suitable tool.

- It is important that the brazing is done quickly, in no more than 1 minute, to reduce the possibility of heat conducting to the unit and causing damage, and for this reason only an oxy-acetylene kit with the correct size nozzle should be used as this would ensure higher temperatures, and correct concentration and spread of the flame than if using other products e.g. Mapp Gas, Propane or Oxy Propane

- Oxygen Free Nitrogen must be swept through the pipe during brazing to prevent oxidization.

**In the case of higher pressure refrigerants such as R410A particular attention must be given to the practice of jointing pipe-work, as in this instance during swaging, in respect to the wall thickness and therefore its strength. If the industry guidelines for a particular diameter pipe suggest they should not be formed, i.e. bent or swaged, then a correctly sized sweat connector must be used. Filler penetration when brazing must also be appropriate.

Access points

Sufficient access should be provided to the system to allow it to be processed and checked. Service and shut off valves have a potential for leakage at the valve stem, gauge ports and connection to the system. Schrader valves which are capped have few potential leak points. Schrader valves should be securely capped, preferably with a hexagonal nut which can be tightened with a spanner. Schrader valves should be specified/purchased with a hexagonal nut cap rather than a knurled cap.

When installing RAC system pipe work can it be located behind plasterboard walls or ceiling?

The Regulation does not restrict the location of refrigerant pipe work and it does allow indirect leak checks to be made. Commission Regulation 1516/2007 Article 5.1 allows for both direct and indirect checks. If an effective indirect leak test can be carried out then it is possible to locate pipe work in locations that are inaccessible for direct leak testing.

If a leak detected via indirect testing and direct testing of exposed components shows no leakage then you must assume the leak is in the inaccessible location and you will need to gain access to locate and repair the leak.

If there is only brazed pipe work in the inaccessible location then it is reasonable to use indirect testing and accept there is a small risk of needing to gain access.

It is not considered good practice to locate “leaky” components like uncapped valves behind an inaccessible ceiling or wall.

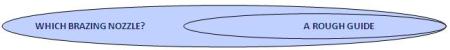

The following are the points key to brazing reliable connections:

- The use of turbo torches should be avoided for brazing pipe work on RAC systems;

- The oxy acetylene torch nozzle size should be appropriate for the pipe outside diameter ( see table ). An oversized nozzle is acceptable for small pipes, but an undersized nozzle on larger pipes will not provide enough heat for good braze penetration;

- The correct jointing materials should be used, e.g. in accordance with the user’s specification with regard to silver content in copper phosphorous rod;

- Surfaces should be clean and free of grease and oil;

- Oxygen free nitrogen should be purged through pipe work when brazing.

- Copper should be annealed before swaging (including softer coiled copper);

- There should be access to the joint to complete the joint in position;

- A mirror should be used to check the back side of joints;

- Pipe should be cooled naturally and not quenched immediately after brazing.

Brazer training and qualifications

Brazer training enables brazers to check the quality of their joints and hence improve the standard of their brazing. The British Refrigeration Association and the CITB brazer schemes are qualifications which include a practical test. The candidate brazes a test piece comprising a number of joints of different sizes and orientations, copper to copper and copper to a dissimilar material. The joints are then cut open and examined for penetration.

This is an F-gas requirement for installations that include or are designed to include F-gas if the operative does not hold the F-gas City and Guilds 2079 or the CITB J11 by July 4th 2011.

Note: the personnel must be supervised by someone who holds a 2079 or the CITB J11.

The key points of a specification to minimise leakage are:

- To minimise the potential for leakage, for example by using a few connections as possible and brazing them; To minimise the quantity of refrigerant in the system;

- To reduce the direct environmental effect of leakage by using low GWP refrigerants where possible.

Brazing

| BOC Combi and Combi-lite welding nozzles | ||||||||

| Tube Size | Size | Size | Size | Size | Size | Size | Size | Size |

| 2 | 3 | 5 | 7 | 10 | 13 | 18 | 25 | |

| Capillary | ||||||||

| 5/16 | ||||||||

| 1/4 | ||||||||

| 3/8 | ||||||||

| 1/2 | ||||||||

| 5/8 | ||||||||

| 3/4 | ||||||||

| 7/8 | ||||||||

| 1 1/8 | ||||||||

| 1 3/8 | ||||||||

| 1 5/8 | ||||||||

| 2 1/8 | ||||||||

| 2 3/8 | ||||||||

| 2 5/8 & above | ||||||||

| The above table is a rough guide to the correct welding nozzles needed for brazing refrigerant grade copper tube based on our experience and would be dependant of course on the pressure of the oxygen and Acetylene. However, other factors that should also be taken into account would be whether the pipe was being brazed or silver soldered, being fitted into a compressor valve body where there might be a large heat sink or where a large flame could cause damage. Generally speaking the more proficient engineer would tend to adjust the gas pressures before considering changing to the next size nozzle. |

having sharp, square edges. Nozzle faces can be dressed with the use of

a fine file a and the orifices cleaned with the appropriate nozzle

cleaner.